During my last trip overseas, I came across Henry Weston Vintage Oak Aged Cider while I was browsing ciders in Tallinn, Estonia. The Weston Cider was great, even at 8%+ ABV, the cider was smooth and the tannic properties along with hints of vanilla that the oak added to the cider balanced well.

At that point, I knew an oak aged cider would be next on my list. So, I did some research while I was killing time at the airport and when I got home I was ready to make my next experimental batch of homemade hard cider.

A cider aged on oak has been something I have been thinking about making for a while but I wasn’t sure what the best method would be on a home cider making scale.

There are several options whether it is in an actual barrel or not. Smaller oak barrels, oak chips, oak cubes, and oak spirals all seemed like great options so I needed to do some more research to find a starting place.

The Downside to Oak Barrels:

As you can imagine, quality oak barrels can be expensive and it seems like the craft size barrels go for an even higher premium. Oak barrels also require a extra care before and after use to make sure they are clean and sanitized well enough for fermenting or aging cider in. Also, if they are left to dry out, it can be hard to get them watertight again.

That being said, true oak barrels are hard to replace in any verity of alcohol production, but there are a few more options to explore that offer a cheaper cost of entry and allow for flexibility in batch sizes.

I decided the best way for me to achieve the aged oak flavor in a cider would be to use oak chips, cubes or spirals. These pieces of oak are generally added to the secondary (although they can be added to the primary) and the hard cider ages on the oak while in the fermenter. This allows the cider maker to get the barrel aged cider without a barrel.

Chips, Cubes or Spirals:

Oak chips, cubes, and spirals offer the home cider maker many different options for infusing the oak flavors into hard cider. While an oak barrel provides a limited amount of surface area and volume, chips, cubes, and spirals can be added in varying amounts and at different stages to achieve the desired results. Also, the oak flavor can be achieved quicker because of the increased surface area.

As an added bonus the oak comes in several styles such as light, medium and dark toasted along with French or American oak. They are a lot cheaper than barrels too!

Oak Chips:

Oak chips are the cheapest and more readily available product I could find. The chips can be weighed out and added in any amount desired. The downside is that they may leave small chips or particles in the finished cider so a muslin bag may be needed depending on the application. Of course, the use of a siphon and good technique will minimize any risk.

Oak Cubes:

Oak cubes offer a clean surface area and can be added cube by cube without the need to measure. The ones I have seen are smooth and clean so no particles of oak will be left in the cider after aging.

Oak Spirals:

Oak spirals are great because the surface of the oak stays exposed and they can easily be broken into smaller pieces depending on the size of the batch or flavor desired. These seemed to be very popular and I plan to give them a shot next time.

Test Batch:

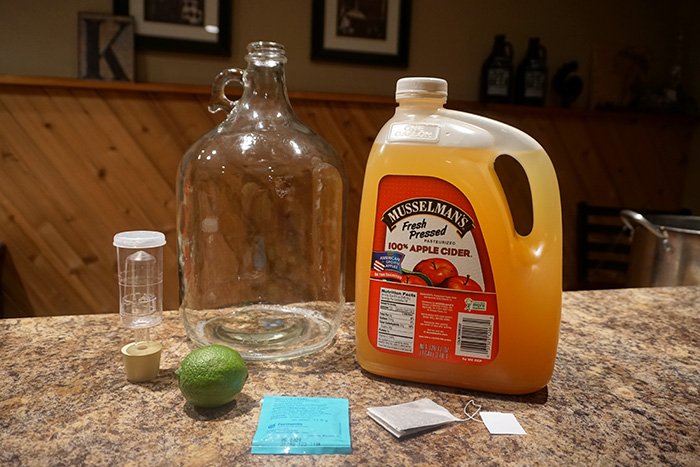

Because of the availability and cost, I decided to experiment with the oak chips first. To get started I made a simple batch of hard cider with Nottingham ale yeast. This cider is the base that I like to start with when I begin an experiment because I know how it tastes straight and I can differentiate the flavors easily. At about 5.5% ABV and slightly dry, the cider provides a good base.

New to Cider Making? Check out the guide!

I took the fermented hard cider and racked it into 3 glass quart jars with the different amounts of oak chips in each. I planned to age each cider for three weeks, testing after each week to determine the results.

Looking at the package of the LD Carlson Oak Chips, it suggests the 4 ounce package is sufficient for up to 25 gallons of wine which didn’t seem like much oak. Then calculating it to a one gallon batch, it would only be about 4.5 grams of oak chips.

Looking at suggestions from others online, I found that good results were achieved by using between 8 and 12 grams of oak per gallon. So, I decided to go with 4, 8, and 12. Of course, I used quart jars, so the weights were divided by 4 to equal 1, 2, and 3 grams per quart. (4 quarts in a gallon)

A common recurring piece of advice I read was that cider can easily be over oaked and you can always add more but you can’t take it away. So keep that in mind too.

Oak Preparation:

Before placing the oak chips in the cider, I considered how I could sanitize oak chips without compromising the experiment but decided that would be difficult. Instead, I followed the instruction on the package and soaked the chips in water before adding them to the fermenter without any special sanitation procedure. I haven’t had any contamination issues so far and since there is alcohol in the cider at this point, I believe it is relatively safe.

Ways to sanitize oak for cider

- It has been suggested to soak the oak chips, or any of the others, in a neutral spirit to sanitize the wood but I feel the spirits would add additional flavors to the cider other than just the true oak.

- Boiling or pressure cooking the oak in a small amount of water could be a viable method but the additional liquids at higher temperatures make remove some of the flavor similar to how tea is made.

- The last method is to toast the oak yourself in an oven. This method seems to be the best option and you can control the amount of toasting and do not remove any of the flavors as the other liquid methods do.

The Results:

At the time of writing this, the cider has been aging on oak for just short of a week. As soon as I get my tastings done I will be back to give an update!

I really appreciate your scientific approach to testing varying amounts of reproducible Oak chips to cider. This seems to be an area where a general starting point is easily identified online, but it is hard to find resources regarding the impact of 2 factors beyond general trends:

1) Starting amount of oak per volume (and impact on rate of Oak flavor extraction)

2) Duration of aging, and impact due to increased Tannic extraction over time.

It’s clear there is a balancing act of aging time and initial amount for both wood chips and wood cubes – and that wood chips increase surface area (and thereby rate) compared to wood cubes, but everything beyond this seems to be guesswork, personal preference and anecdotal single data points.

If you could provide tasting notes out to 2-3 months, that would be absolutely amazing, since “Oak” flavors tend to peak around 2-4 weeks with chips and then they mellow out and astringent tannins become more prominent over longer periods of time.

Can you elaborate on what you’ve found for cleaning and sanitizing oak barrels prior to use for cider? I’ve picked up two 5 gallon American oak barrels from a local distillery for some longer term experiments. One of the barrels was a bit dry and took about 10 gallons before it stopped leaking. They have both been sitting full of water for a couple of weeks now.

I have two 5 gallon test batches in primary, each with the same apple mix but one fermented with EC-1118 and the other with Cider House Select. In another week or two I’ll move them to their own barrel and let them sit in the basement for 6 months, or more depending on how impatient I get. The barrels first life included single malt whiskey so undoubtedly I’ll get some flavor from the spirits.

I have tried French oak spirals with medium char on two 5 gallon batches with various apple blends. They aged in bulk with the spirals for between 2 and 3 months and both batches turned out quite nicely.

Hi Rob, I apologize for the late response. How did your barrel cleaning go?

I really haven’t had much experience with barrels yet, the only one I have used was cleaned and stored with water in it after having spirts. I assumed the spirits were effective at keeping the barrel sanitized.

I have read about using barrel cleaning products such as Barrel-Kleen followed by a citric acid wash. It is supposed to take care of potential mold or acetobacter.

I plan to get my hands on a new barrel soon and will have to do a thorough write up on what I learn.

My experience with aging on oak chips/spirals has been great so far, I’m glad to hear others are happy with the results too.

Cheers!

Another suggestion that I plan on trying is to char the oak chips. I use a specified amount in a spare Pyrex measuring cup. I use a propane torch to char the wood to a medium char. Adding this will definitely darken the color, but will add nice vanilla notes. I have tried this in distilled applejack, and it is outstanding.

No results?

I’d be happy to read the tasting updates as I intend to experiment with wood chips soon 🙂

2023 and still waiting with bated breath to hear how it turned out! I have 2 batches coming out of primary in the next week, and getting ready to apply oak to my cider. I would appreciate any previous results

Also curious about the results. I added 15g of oak chips to a gallon of cider in secondary and that was clearly too much. It did introduce nice tannins, but I was forced to rack after leaving them in for 12 hours. Any longer would’ve destroyed the batch imo. Trying to figure out which amount of oak chips I can leave in for around 2 weeks or so, which brought me here 🙂

Do you have any results? How about priming for carbonation post-ageing? How long will the yeast stick around?

Any results?

I am wondering about results as well, pretty disappointing there are none, isn’t it?!

Anyway, I asked about oak chips in local brewing store and recommendation I was given by experienced guys there: 1gr of chips per 1 liter of cider. Add chips during secondary fermentation, no earlier than 7-10 days before end of this fermentation. At the end, taste the result and if feel you’re still lacking of the taste, make a concentrated ‘oak tea’, pour some of it in, taste and repeat until you’re happy with result. Then bottle it up, leaving chips in the jug. This sounds to me as safe approach, I’m yet to try it out.

Did author of the experiment survive? 🙂