Making hard cider with store bought commercial apple juice is probably one of the easiest ways to make a cider and perhaps alcohol in general. At least a decent tasting one.

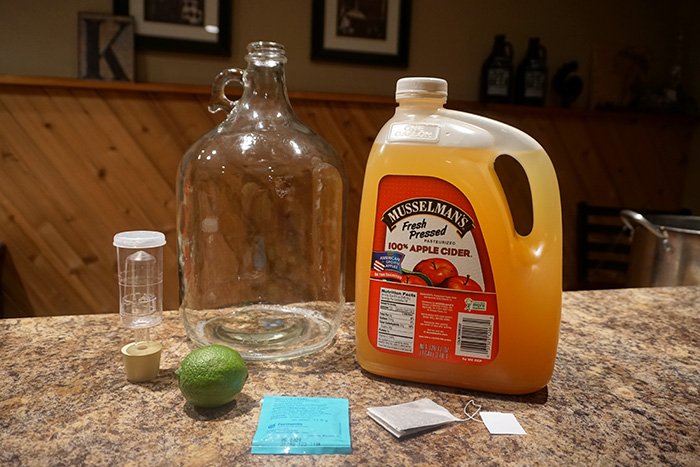

Not everyone is lucky enough to live close to apple orchards where the freshest cider can be found. Luckily, a store bought cider such as Musselman’s Cider can be used to achieve decent homemade hard cider results! The commercially available cider is also about half the price of a fresh pressed cider and typically pasteurized which eliminates the need for campden tablets.

The most important part of this recipe is to make sure the juice does not have any preservatives. Preservatives will not allow the yeast to flourish so you will not get any alcohol production! Ascorbic Acid (Vitamin C) is commonly added to store bought apple juice and will not harm the cider fermentation process.

These commercial types of apple juice typically lack tannin so if you prefer the mouthfeel of tannin in your cider, consider adding a tannin powder or tannin from tea to enhance the cider. Many other flavors can be imparted to improve the flavor of this cider such as ginger, berries or other fruit juices.

Five Essential Pieces of Equipment

How I Make Hard Cider With Store Bought Juice

I started with 1 gallon of Musselman’s Apple Cider that I purchased at a local grocery store. Using a hydrometer, I measured the original gravity of this juice at 1.044 which I calculated would produce around 5.5% ABV if I fermented it to near dry, or near 1.002 FG. An ABV in this range is perfect for me so I did not make any sugar additions although apple juice concentrate can be added to boost the sugar content and in turn raise the expected final ABV.

After I took a hydrometer reading I poured the cider into a one gallon carboy along with one teaspoon of yeast nutrient to ensure strong fermentation.

I then added 1/4 package of Safale S-04 ale yeast, which is one of my favorites for ciders. The flavor of the ale yeast is complementary and it does not ferment as dry as some other yeast.

Fermentation began strongly with a nice layer of krausen forming on top. The krausen settled and the yeast sank within 48 hours as the fermentation vigorously bubbled. Within 72 hours the fermentation slowed from a bubble per second to around a bubble per 30 seconds. At this point, the specific gravity measured 1.004 and within a few more days it stabilized at 1.000.

Once fermentation ended, I racked the cider to a secondary fermenter and allowed it to clear for a couple weeks. At this point, the cider tasted quite nice and should age well.

Cider Results:

Original Gravity: 1.044

72 hours: 1.004

Final Gravity: 1.000

AVB: 5.74%

For bottling, I used 12-ounce bottles and made some experimental tannin and sweetener combinations that I am looking forward to!

Hard Cider From Store Bought Juice

Materials

- 1 gal Apple Cider

- 1 tsp Yeast Nutrient

- 1/4 pack Safale S-04 Yeast

Instructions

- Clean and sanitize all cider making equipment before starting.

- Pour the Apple juice into the fermenting vessel.

- Take a hydrometer reading to measure the original gravity and record.

- Add yeast nutrient if desired.

- Pour the yeast into the fermenter.

- Close the fermenter and install an airlock filled with sanitizer.

- Allow the cider to ferment in a cool and dark place for about two weeks.

- Cold crash, rack and bottle.

I’ve been making hard cider with Stater Bros apple juice which is only $3.89/gal. I’ll add 5 gallons of apple juice to a homebrew fermentation bucket and 5 cups of standard granulated sugar. The fermentation usually only lasts about 9 days to get to a FG of 1.000.

OG = 1.070

FG = 1.000

9% ABV

I will backsweeten with one 12 oz can of apple juice concentrate. This will make a dry hard cider. You can add more cans of apple juice concentrate if you prefer a sweeter cider.

I force carbonate using a keg. So for under $25 I’m able to make 5 gallons of delicious, strong cider in only 9 days. The cider does improve with age, but I drink it as soon as fermentation is ended.

Some dry wine yeasts that ferment well and provide good fruity taste are:

Red Star Cotes de Blanc

Red Star Premier Cuvee

Red Star Premier Blanc

I have also tried the TreeTop Honey Crisp Apple Juice which is also inexpensive and delicious.

Thanks for your recipe both in the post and the comment!

This is what I was looking for, I want to brew 19 litres (for Corny keg) what else do I need to know?

After you ferment and then if you secondary and wait till it clears you will need to add potassium sorbate 24 hours before you add any sweetener that may ferment. I use a can of concentrated apple juice or wine sweetener to taste

Also, usually in october, Costco had great cider for hard cider making